Manufacturing Processes

At Pioneer Strategic Sourcing, our manufacturing processes involve CNC machining, private labeling of finished goods, sub-assemblies or components, and more.

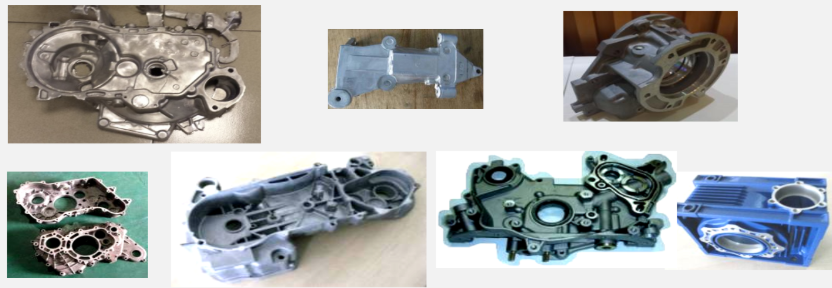

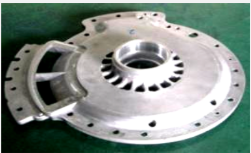

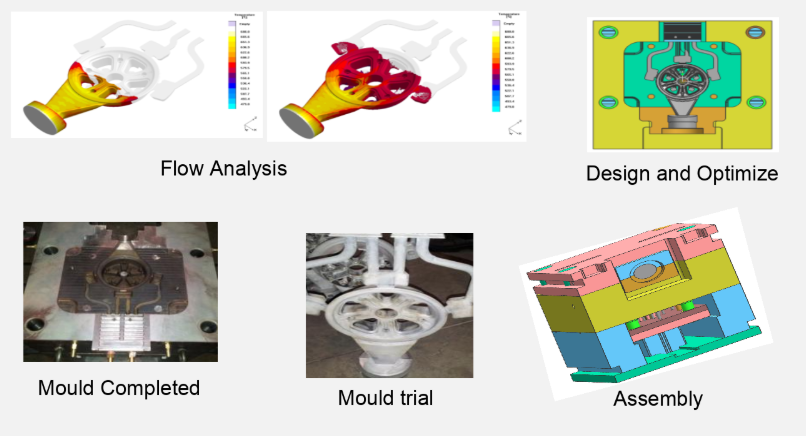

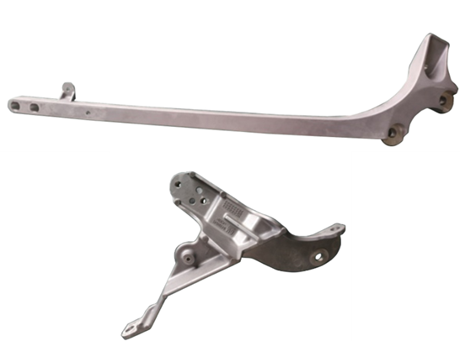

In this process, we inject molten metal or metal alloy at high speed and pressure into the mold. This technology can create large light alloy parts at great speed and high volumes.

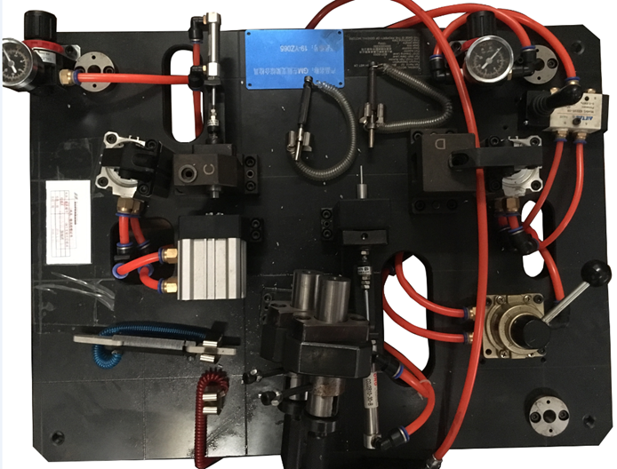

Fully Automated production lines

Through this process, we try to achieve a level of vacuum in the die cavity just before casting, so that excess gas will not be trapped in the casting to create blisters during heat treatments.

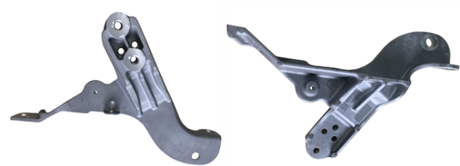

Through our stamping operations, we shear strips of metal into specific shapes at ambient temperatures. The process usually involves a series of one or more discrete impact steps. We apply compressive force to pre-formed blocks of metal at high temperatures through forging.

This is the process where we build components into component assemblies, to include in larger end items. It involves combining of components, to create a parent product that one can assemble. We send sub-assemblies to the assembly line for a final integration into the end item.

Engine casting & Side rails, Appliance and Technology Components

We manufacture thin-walled plastic parts used to build a wide variety of applications through the process of injection molding.

We will manufacture private labelled products to your specifications, and deliver high quality, at lower costs and in a quicker turnaround time.

This is the manufacturing process where the movement of factory tools is determined by computer software. With this process we control a variety of complex machinery. With CNC machining, we make three-dimensional cutting tasks achievable with a single set of commands.